Core Plasticizing Technology

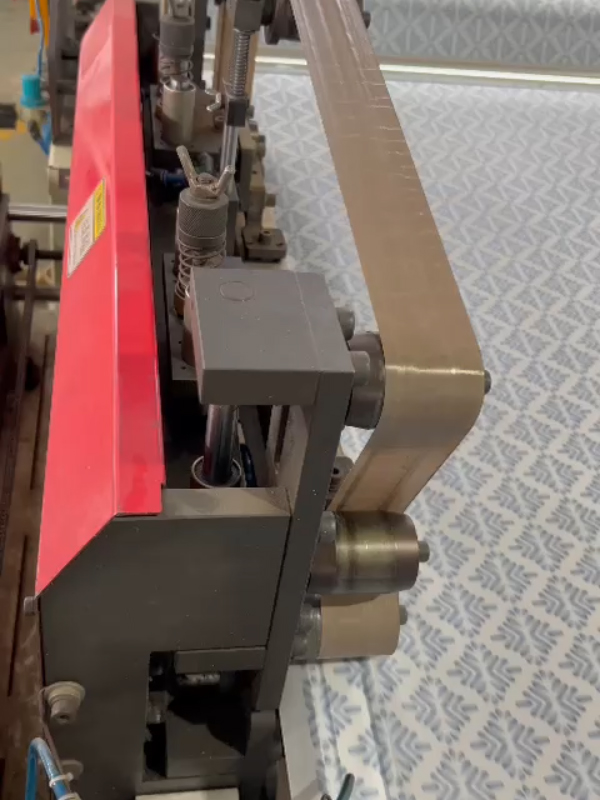

Extrusion Process

The extrusion process is indeed one of the most versatile and user-friendly manufacturing processes. Both sheet extrusion and cast film extrusion can be used to produce a wide range of products using materials such as PE, PP, HDPE, and EVA. We use these processes to manufacture a variety of items including Shower Curtains, Drawer Mats, Desk Mats, Table Covers, Bottle Carriers, Flexible Chopping Boards, and many more.

Injection Moulding Process

Injection Molding is one of the most widely used manufacturing processes for a variety of applications. At our Injection Molding Unit, we manufacture Artificial Plants & Flowers, Shower Curtain Hooks & Rings, as well as Plant Pots for both live and Artificial Plants, using PP and PE materials.

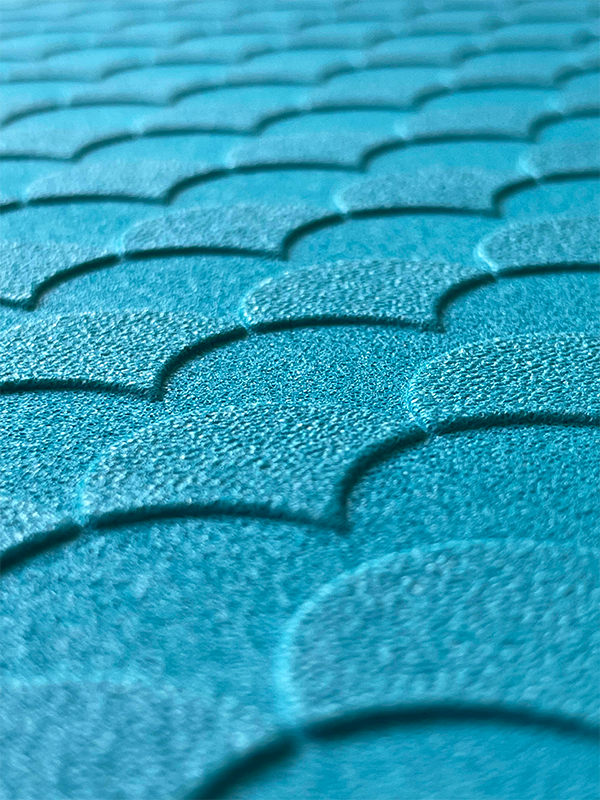

Compression Moulding Process

We utilize Compression Molding techniques to produce three-dimensional molded EVA Foam products, including Yoga Mats, Bath Tub Mats, Table Placemats, Spa Slippers, and Baby Shower Caps.